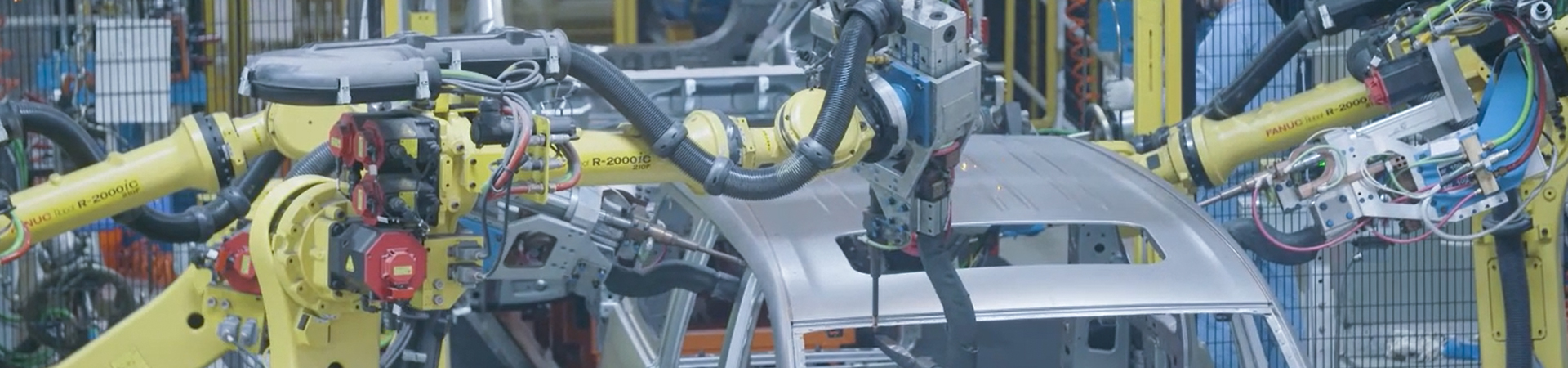

The output current of welding gun is large and the welding time is short

Welding gun' s strength is higher

Welding gun pressure is high

Curved Surface Electrode

The gun arm is equipped with a cooling copper bar

Welding gun can be equipped with pressure feedback device

C TYPE BASIC PARAMETERS

Weld gun force:MAX 8000N

Maximum short-circuit current:50KA

Transformer capacity: 225KVA X=50%

Weld gun stroke :130/180/2 80mm, Can also be increased according to the requirement

Total weight of welding gun:≤164KG

Weld gun cooling water flow:≥15L/min

Electrode cap: φ20mm

X TYPE BASIC PARAMETERS

Weld gun force:MAX 8000N

Maximum short-circuit current:50KA

Transformer capacity: 225KVA X=50%

Weld gun opening:24*/19°

Total weight of welding gun:≤20OKG

Weld gun cooling water flow:≥15L/min

Electrode cap: φ20mm