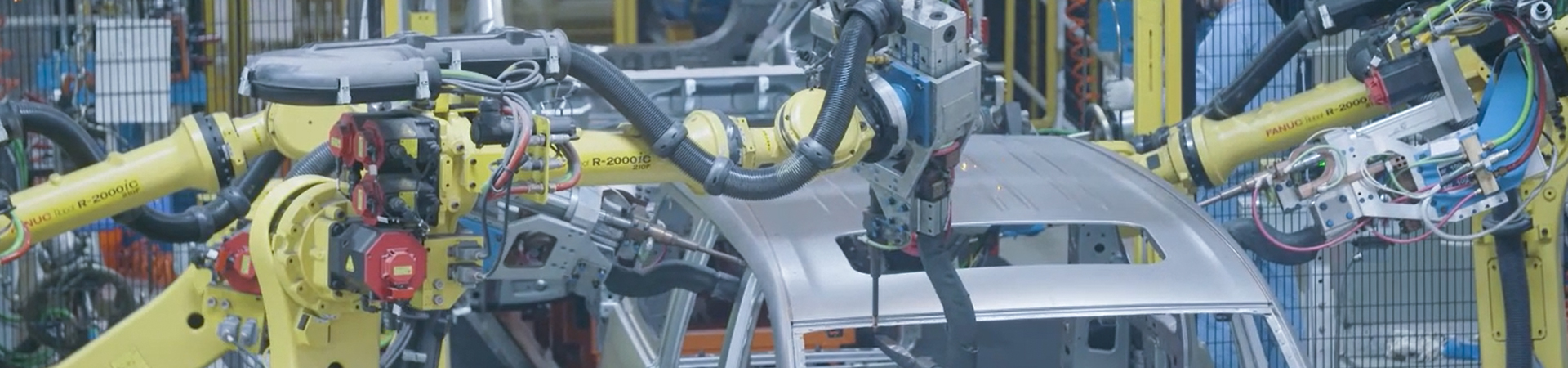

It has 256sets of welding specifications

The constant phase Angle (PHA) ;Constant current control mode (KSR)

It has adaptive function

Reserved networking function

Communication mode: I/O ,Devicenet, profinet, profibus, EthernetIP, CC-link

There are two cooling methods: water cooling and air cooling

Handheld programming and computer software programming